|

"Technological innovation is not a process: it is the means to achieve our goals"

|

||

|

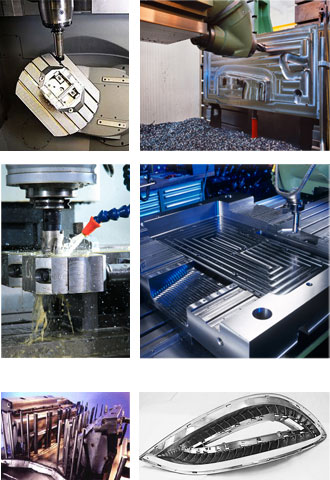

In addition to being made up of highly experienced, professional personnel, the production department at Mould solutions has modern machinery and equipment, and is up to date with the most recent technologies: 5-axis high-speed milling machines and pallet changer, wire cutting and wire EDM machines, numerically controlled drilling machines, spotting press and injection machine for mould testing and sample parts production. Mould Solutions can boast many years experience in making moulds for highly complex aesthetic components and technical parts, and besides the traditional mono colour/component we make: 2K bi-component rotative, blade or translation moulds (plastic + rubber), with 2-3- rotating colours, and gas injection moulds. Especially with reference to the Automotive sector, Mould Solutions is specialized in design and mould manufacturing for: |

-Head and rear light units: multi K lenses and frames, reflectors and housings.

|

|

|

||

|

||